Email: info@massfilling.com Tel: +86 133 5803 8863

It's used to inject pen barrel tip etc.

Plastic Pen Barrel Injection Molding Machine:High-Precision, Efficient Pen Production

In competitive stationery manufacturing, the plastic pen barrel injection molding machine is a core asset determining product quality,

efficiency, and profitability. Pen barrels require strict dimensional accuracy, smooth surfaces, and consistent thin walls – all dependent on

specialized injection molding technology. Whether expanding a small factory or optimizing a large enterprise, this machine is critical for market

competitiveness.

Our machines are engineered exclusively for pen production, combining precision clamping, high-speed injection, and intelligent controls to deliver

consistency, reduce waste, and shorten cycles. Below are key features, applications, and benefits to guide your decision.

Dimensional accuracy is non-negotiable for pen barrels. Our servo-driven clamping system (50–200 tons) ensures tight mold sealing, eliminating

defects like flash and warping. The precision injection unit with a mixing screw uniformly melts PP, PS, ABS, PC, and recycled plastics. Adjustable

injection speeds enable fine-tuning for different pen sizes, guaranteeing consistent wall thickness and perfect compatibility with refills.

Compared to traditional hydraulic machines, our servo-driven models cut energy consumption by 30–50%. The motor operates only during key

processes, reducing electricity costs and noise (below 75dB) for an eco-friendly workshop.

A user-friendly touchscreen stores up to 100 production recipes, enabling quick product changeovers in minutes. Real-time monitoring of critical

parameters alerts operators to anomalies, minimizing defects. Minimal training is required for operation.

Our machines work seamlessly with custom molds for standard, ergonomic, or logo-embossed pen barrels. Adjustable mold mounting and ejection

systems accommodate diverse designs, allowing product line diversification without extra equipment.

Built with high-quality components (hardened steel screws, wear-resistant liners), the modular design simplifies maintenance. We offer a 1-year

warranty and lifetime technical support for long-term reliability.

Application Scenarios

High-tonnage models deliver continuous high-volume output for major stationery brands, meeting peak season demands. Energy efficiency and

centralized monitoring optimize 24/7 operation.

Mid-range models excel at small-batch, customized production (branded pens, souvenirs). Quick mold changeovers ensure precise logo placement

and color consistency.

Engineered for recycled plastics, our machines minimize defects and waste ( reducing costs and environmental impact for sustainable stationery brands.

Low-tonnage models produce small batches of luxury, medical-grade, or ergonomic pens, with adjustable parameters ensuring flawless finishes and tight tolerances.

Entry-level models offer cost-effective solutions for local suppliers, with user-friendly controls and compact design fitting small workshops.

• Efficiency: Fast cycle times and quick changeovers maximize productivity.

• Cost Savings: Reduced energy use, material waste, and maintenance costs.

• Quality Consistency: Uniform accuracy and surface finish meet strict standards.

• Versatility: Produce gel pens, ballpoints, markers, and custom designs with one machine.

• Specialized Design: Engineered exclusively for pen barrel production, outperforming general-purpose machines.

• Cost-Effective Operation: Energy efficiency and low waste boost profit margins.

• Comprehensive Support: Pre-sales consultation, installation, training, and after-sales service.

Our plastic pen barrel injection molding machine combines precision, efficiency, and versatility to meet the needs of all pen manufacturers.

From startups to large enterprises, it enables high-quality production at lower costs while reducing environmental impact. Contact us today for details, quotes,

or factory visits to elevate your business.

1.100% clamping use ratio, 10%-20% higher than that of traditional structures;

2. Less fins on the finished products;

3. 2%-6% raw materials saved from production than that of traditional structures;

4. Effective protection for the mould, molding board, and pull rod;

5. A opening stroke 10%-20% longer than that of traditional structures;

6. Less deformation caused by cooling of the products.

Specification

Injection Part | Item/type | Unit | MA-180 | ||

Screw type | A | B | C | ||

Screw diameter | mm | 40 | 45 | 50 | |

Screw diame-ter ratio | L/D | 22 | 22 | 20 | |

Theoretical injection volume | cm³ | 276 | 350 | 432 | |

Injection volume (PS) | g | 251 | 318 | 393 | |

Maximum rate for inject-ion to air | cm³/s | 126 | 159 | 196 | |

Injection pressure | MPa | 215 | 169 | 137 | |

Injection stroke | mm | 220 | |||

Maximum injection speed | mm/s | 111 | |||

Maximal Rotational Speed of Screw | r/min | 210 | |||

Clamping Part | Clamp Tonnage | KN | 1800 | ||

Toggle stroke | mm | 490 | |||

Distance between tie bars | mmxmm | 465x418 | |||

Maximum mould height | mm | 520x470 | |||

Minimum mould height | mm | 200 | |||

Ejection stroke | mm | 150 | |||

Ejector force forward | KN | 45 | |||

Ejector force backard | KN | 30 | |||

Amount of die thimble | Pcs | 1+4 | |||

Others | System pressure | Mpa | 17.5 | ||

Motor power | KW | 18.5 | |||

Heater power | KW | 9.95/1095 | |||

Quantity of temperature-control zones | 1+4 | ||||

Bucket capacity | KG | 25 | |||

Oil tank capacity | L | 230 | |||

Boundary dimension(L×W×H) | m | 5.5x1.5x1.9 | |||

Machine weight | Ton | 5.6 | |||

Packaging & Shipping

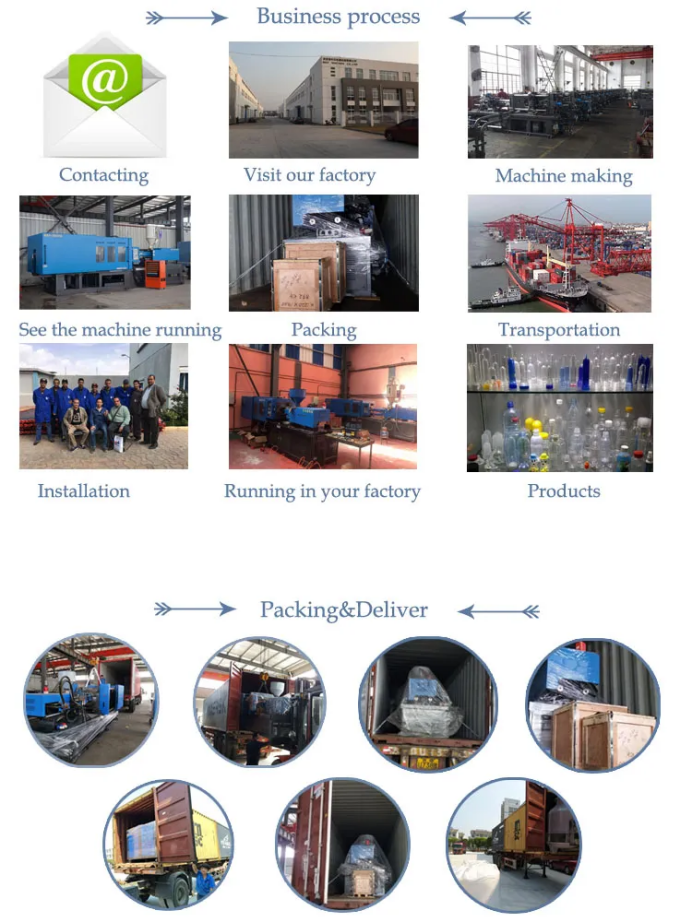

Business process

1. Inquiry-Pofessional Inquiry

2. Confirm the price, leadtime, payment term etc

3. Sheenstar sales send the proform invoice with sheenstar seal

4. Customer make the payment for deposit and send us bank receipt and offer samples

5. Inform customer has got the deposit and start to production

6. Middle production- send photos to show the production line which you can see your products in. Confirm

the estimated delivery time again

7. Clients make payment for balance and Sheenstar ship the goods. Also can accept payment term-Balance

against B/L Copy Or L/C payment Term. Inform the tracking number and check the status for clients.

8.Order can be say “finish” when you receive the goods and satisfy with them.

9. Feedback to Freedom about Quality , Service, Market Feedback & Suggestion. And we can do better.

Packing&Deliver

We take care of our machine packing and loading.

Injection machine with anti-rust process, make sure no rust due to ocean shipment.

Each package would be fixed stable inside container, make sure no damage or crash during whole shipment.

We should take photos of loading, and send to you for reference.

Contact: Linda Ma

Phone: +86 136 1624 7328

E-mail: info@massfilling.com

Whatsapp: 8613616247328

Add: Leyu Development Zones,Zhangjiagang City,Jiangsu

We chat