Email: info@massfilling.com Tel: +86 133 5803 8863

Full automatic blow molding machine is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

6000BPH Automatic 4 Cavities Blowing Machine For 500mL

production Introduction:

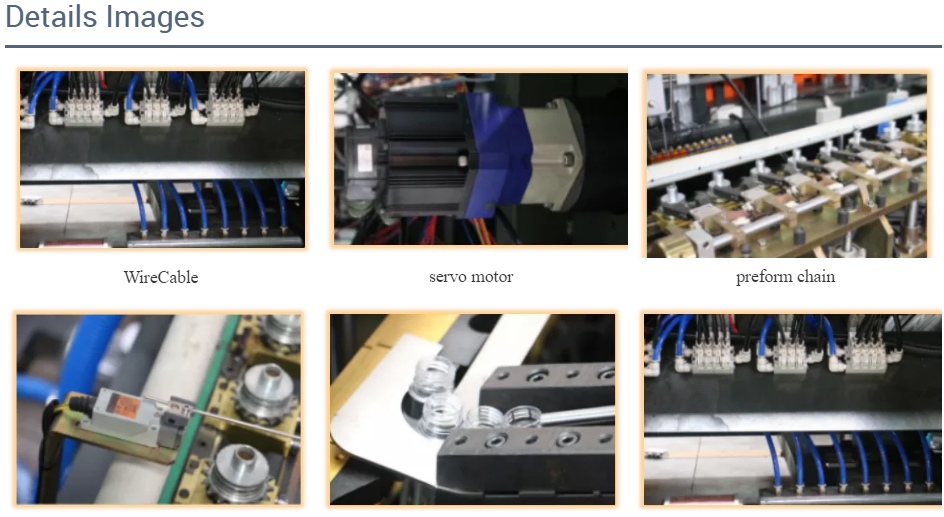

1. Electrical

1.1 PLC will protect and control the blowing procedure of the machine

1.2 Operation platform directly controls the machine by EV human-computer interface which will display the production situation intuitively, the parameter can be properly adjusted in the interface according to the blowing technology.

1.3 The human-computer interface has production situation, control parameter and alarm and other interfaces

1.4 Air throttles are fitted at both ends of cylinder, which will make the whole machine more stable

2. Preform scrambler

2.1 The stepless speed regulating of preform loading is accomplished

2.2 Simple structure, widely application

3. Heating part

3.1 Stale infrared ray heating system has 4 heating zone, each of them are controlled saperately

3.2 Hangzhou Xizi module and intelligent control module accomplish the gaol of heating every part of preform through adjusting the voltage of infrared ray lamps

3.3 Induced air device overcomes the convection of air, better for stabling heating environment, improving heating effeciency

3.4 Air cooling and water cooling devices avoid the neck from being heated to disformed

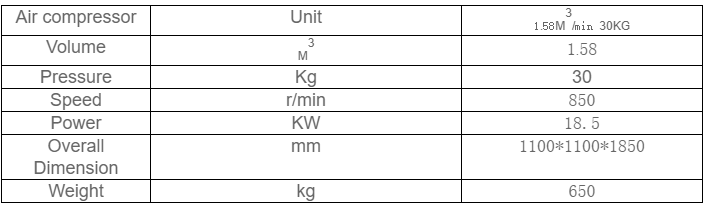

4. Blowing machine mold frame

4.1 The mold frame system is driven by action cylinder will move in the guiding rail accurately and stablely

4.2 Quick mold closing and pneumatic high pressure mold locking devices efficiently solve the mechanical mold locking problems such as mold expand and big mold closing line and etc.

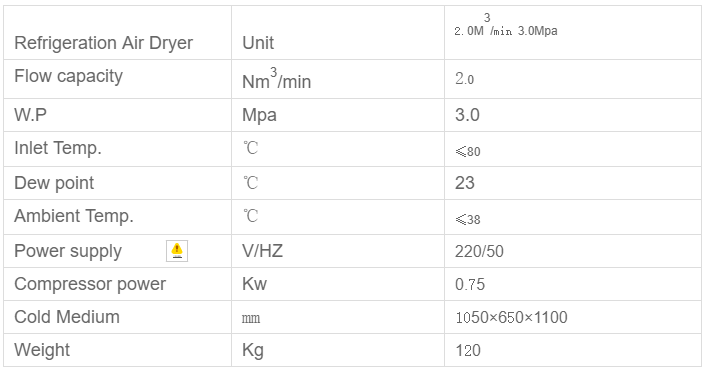

5. Locating device

5.1 The whole machine's transmission is driven by the same power, so the synchronism is perfect

5.2 Mechanical locating design leads to simple structure and stable running situation

5.3 Imported common standard components are used in the chain guiding rail system, so the system is stable and easy to maintain

6. Transfer arm

6.1 Preform transfer arm is driven by cylinder to turn oven and down the preforms and bottles with the features of good synchronism

Main Techniacl Specifications:

Technique Parameter of blow molding machine:

Functions of auxiliary equipments:

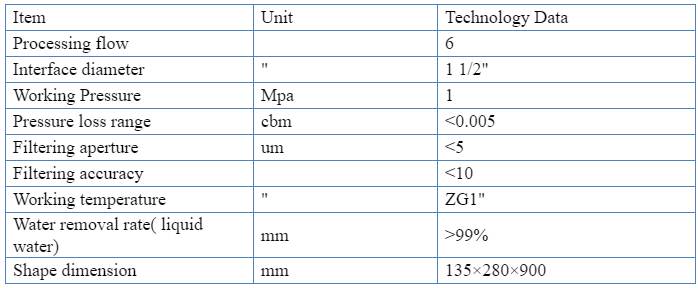

(1) Air compressor is the air source for PET stretch blow molding machine, carrying out the process of compressing air from atmosphere to the required pressure.

(2) Air dryer is to remove the moisture from the compressed air and lower temperature of the compressed air in the heat exchanger.

(3) Air filter is to clear up the impurities out of the compressed air, like carbon-hydrogen, tiny dust and solid particles.

(4) Air tank is to receive and supply air for the machine as storage.

HP air compressor:

Air Cooling Drier:

Packing &Delivery

1. the drinking pure water filling machine is packed by wooden case.

2. The delivery date of drinking pure water filling machine is within 30 days after payment.

Contact: Linda Ma

Phone: +86 136 1624 7328

E-mail: info@massfilling.com

Whatsapp: +8613616247328

Add: Leyu Development Zones,Zhangjiagang City,Jiangsu

We chat